In the world of winches, there are many different technologies that have been developed in order to create a wide range of winches suitable for varied applications in various industries. One type of winch included in this is the air winch.

Powered using compressed air, these are often preferred for their versatility, safety and efficiency when electric or hydraulic solutions aren’t a viable option. In this guide, we’ll discuss the technology behind their operations and the benefits they offer, as well as taking a look at how they’re used in action.

What Are Air Winches?

As their name suggests, air winches use air as their primary power source – specifically compressed air. This is provided by an air compressor, with the compressed air then being stored in a tank or supplied directly to the air winch through a series of hoses.

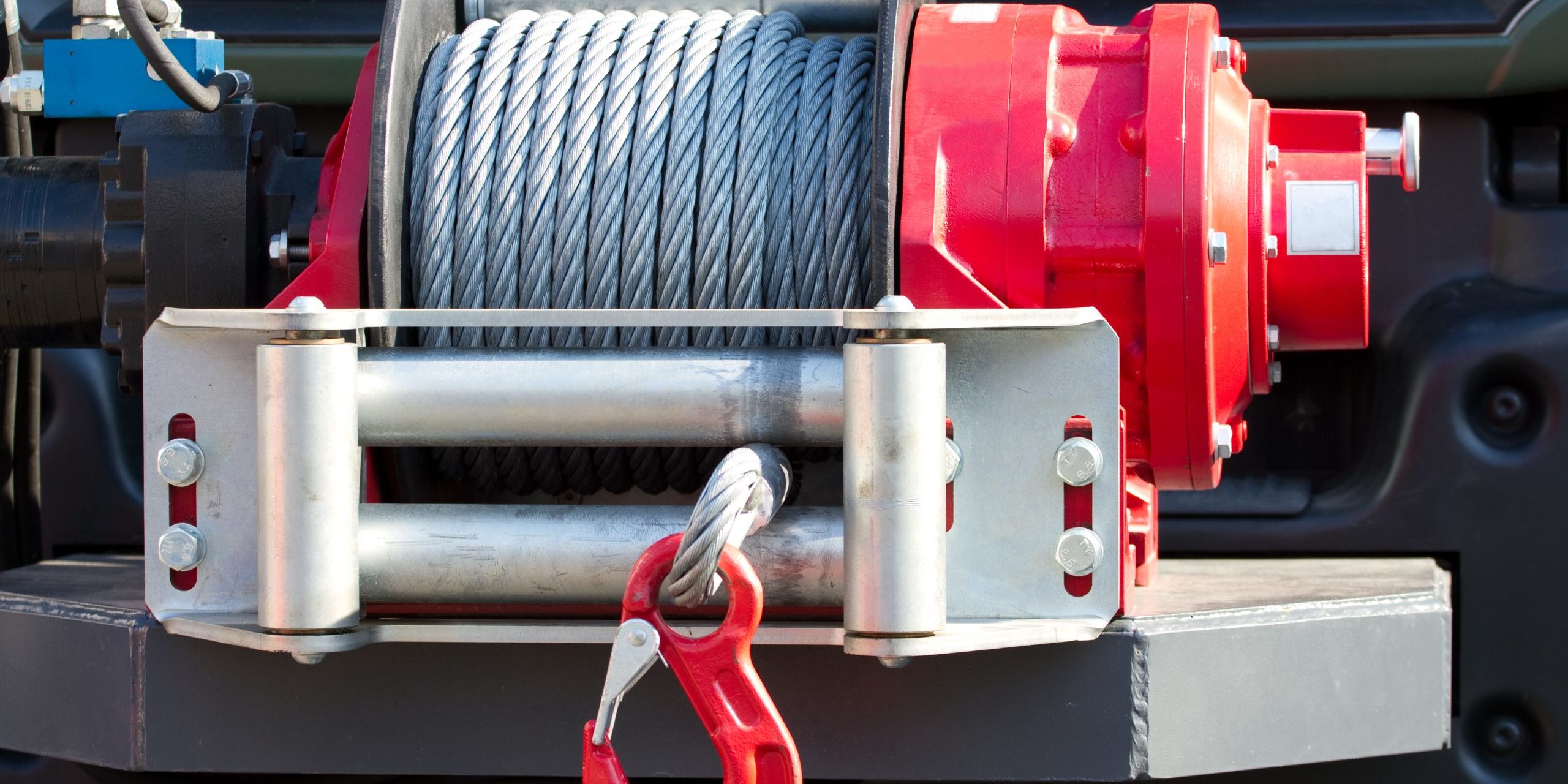

It is then directed to the winch’s air motor – also known as a pneumatic motor – through a set of two ports. The motor works by turning the compressed air into mechanical energy, allowing the motor to turn. Turning the motor, as with any other winch, is what allows the spool (or drum) around which the cable is wound to also turn – thus winding in or releasing the cable.

So, that’s the basic operations behind how they work – but what makes them so reliable? Well, that lies in the other technical processes involved in their inner workings. Their gearbox is just one example. This contains a system of gears that help regulate the speed and torque of the winch, offering the operating user more control over its pulling applications.

It also allows for the direction of rotation to be controlled, enabling the winch to lift or lower loads as required for the specific applications at hand. Depending on which of the two ports the air is directed through is what determines which direction the drum moves, with a directional control valve within the gearbox commanding the winch to operate in one of three positions: forward, neutral or reverse.

Control mechanisms are usually also featured in an air winch, which help to regulate its operations. For example, this could include pneumatic valves or controls, allowing operators to start, stop and control the speed and direction of the winch remotely – such as from a centralised control station.

Advantages Over Alternative Power Sources

Reliable for Their Size

Compared to other types of winches, air winches are incredibly compact and easily portable. Despite their smaller size, they still offer reliable and enormous lifting and pulling power for their weight. This makes them easy to use in a large variety of situations.

They are also easy and simple to operate, allowing multiple workers to be trained on how to use them, thus helping to maximise the efficiency of work tasks and operations.

Low Safety Risk

Arguably the most attractive benefit of air winches, they pose minimal safety risk compared to other types. This is largely due to their lack of electricity, thus making the pneumatic motor inherently spark-resistant, as well as posing no shock hazard.

This makes these winches well-suited for applications that are in hot, cold, dusty, dirty, explosive, wet and other hazardous conditions. It also means that they don’t require any form of special enclosures or additional safety measures to be implemented, which can help increase their efficiency and reduce the costs involved in their application.

Not only are they safer than electric winches, but they’re safer than hydraulic winches, too. Hydraulic winches feature high-pressure hydraulic lines, which could potentially leak and cause a fire hazard, since hydraulic fluid is highly combustible. Since this isn’t present in air winches, this hazard is mitigated.

No Risk of Burning Out

One of the most common risks of electric motors is their risk of overheating and burning out. With pneumatic motors, this isn’t a concern, as they can’t burn out. As such, there is no risk of using them for a long time at full power, allowing them to be used all day without damage.

This is especially useful when a winch is required for tensioning applications, such as holding a barge in place or keeping building components elevated during construction work. Furthermore, no air is used when they’re stalled, meaning less power source is wasted.

Ease of Maintenance

Because air winches don’t require limit switches or overcurrent detection systems, nor special safety enclosures or corrosion-resistant materials, there are less components that need to be maintained. Furthermore, the general composition and benefits of pneumatic winches mean malfunctions are less likely to occur.

Overall, these aspects combined not only reduce downtime, but reduce the associated costs, also.

Their Versatile Applications

Air winches are relied upon in a large array of industrial applications. This is largely down to some of the key benefits that they offer, such as their low safety risk and unlimited duty cycle.

Below are some of their key industries in which they’re used and how.

Offshore Oil and Gas Industry

Air winches are commonly employed on offshore drilling rigs and platforms for tasks such as lifting and positioning equipment, handling pipelines and performing maintenance and construction activities.

Their ability to operate safely in hazardous and corrosive environments makes them indispensable in offshore settings, reducing the risks of fires, electrocutions or malfunctioning equipment – which could otherwise have a knock on effect and cause loads to fall, thus causing even more damage and potential injury.

Furthermore, because of the remote location of these operations, downtime can have a significant effect due to a lack of accessibility. Similarly, emergency services cannot easily and quickly reach these locations if significant injuries occur as a result of failed equipment, which is why a reliable winch is so important.

Marine and Shipping

Air winches also play a crucial role in maritime applications, including cargo handling, towing operations and ship mooring and anchoring. For example, they’re used to deploy and retrieve anchors, lift heavy loads onto ships and assist in docking manoeuvres.

Due to their proximity to water, air winches are ideal for such applications, as getting wet won’t affect their operations and efficiency.

Construction and Building

In the construction industry, air winches are used for hoisting materials and equipment to elevated levels, such as on high-rise buildings and construction sites with limited access.

Many construction companies favour air winches for the combination of their reliable lifting power and portability. This allows them to easily transfer the winch to whichever work site they require it to be used at.

Utility and Power Generation

Utility and power generation industries also utilise air winches. Predominantly, they will be used for tasks such as lifting transformers, positioning transmission towers and installing overhead power lines. However, they are also relied upon for maintenance and repair activities.

The versatility of applications they can be used for within this sector is what makes them such a favoured choice of winch.

Forestry and Logging

Whilst not an industry that winches are typically associated with, air winches can also be used in forestry and logging operations. They can be used for tasks such as pulling felled trees out of forests and woodland, or positioning equipment, such as portable sawmills and log splitters.

Air winches in particular offer a reliable performance in rugged outdoor environments where electric or hydraulic systems may be impractical to install.

Military and Defense

Winches also find applications in military and defence contexts. They are mainly used for lifting and positioning heavy equipment, loading and unloading cargo onto military vehicles and aircraft and supporting logistics operations in remote or harsh environments.

Since explosive materials are also often involved in military operations, air winches are a much safer option to utilise than alternative types, such as electric winches. Their portable size also makes it easier to transport them to the remote locations in which said operations take place.

Entertainment and Events

Perhaps one of the last places you’d expect a winch to be used, but in actuality quite a common one, is the entertainment industry.

They are primarily utilised for rigging purposes during live events, concerts and theatre productions, being used to raise and lower stage equipment, scenery, lighting fixtures and sometimes even performers with safety and efficiency. Although, they can also be used in film production, helping to assist with large scale stunts and bigger sets.

Winch Specialists

So, does an air winch sound like the ideal piece of equipment for your operational needs? If so, then look to us here at Atlas Winch Hire & Hoist Services.

We offer a range of air winches to suit your needs. As winch specialists, you can count on us to provide you with quality winch solutions and offer expert advice wherever it’s needed.

Get in touch with us today to discuss your requirements.